EFS Plastics

Creating post consumer plastic pellets as feedstock for new material.

Listowel, Ontario, Canada

CONDENSED CASE STUDY

IMPACT

ENVIRONMENTAL: Environmental awarenessIncreased environmental stewardshipIncreased resource utilisationPreserving Natural Capital - stocks & flows of energy and materialReduced emissionsReduced waste

ECONOMIC: Increased competitivenessIncreased Manufactured Capital - material goods or fixed assets which contribute to the production process rather than being the output itselfIncreased value creationJob creationNew marketsReduced spendingStimulating innovation

SOCIAL: Developing Social Capital in partnership with others (ie families, communities, businesses, trade unions, educational, voluntary organisations)Increased employment

MODEL

SCALE: Supranational

STATUS: Active

FUTURE POTENTIAL: Scaleable

FACETManufacturing, Material Flows, Plastic, Recycling, Waste Management

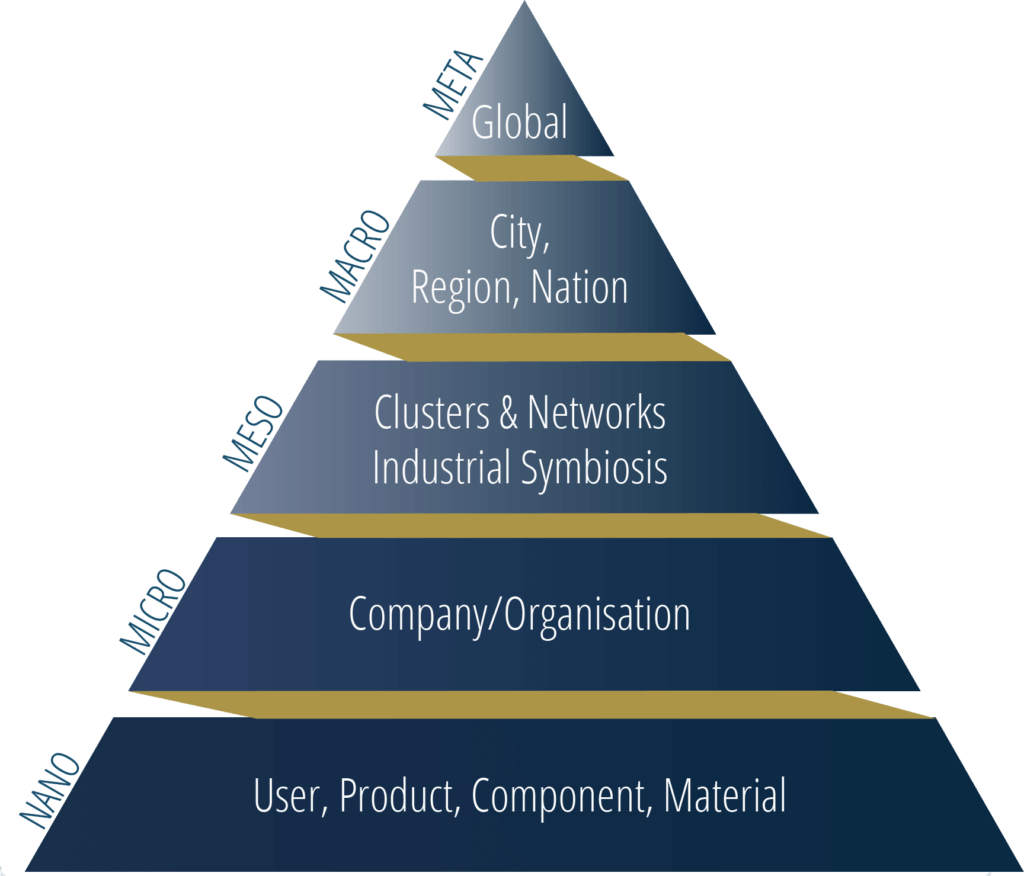

LEVEL: Macro - Cities, Regions, Nations, Micro - Company/Organisation

STAKEHOLDERS: Private Sector

BUSINESS MODEL: B2B - Business to Business, G2B - Government to Business

TECHNOLOGY: Cloud, Networks, Sensors

SOCIETAL READINESS LEVEL:

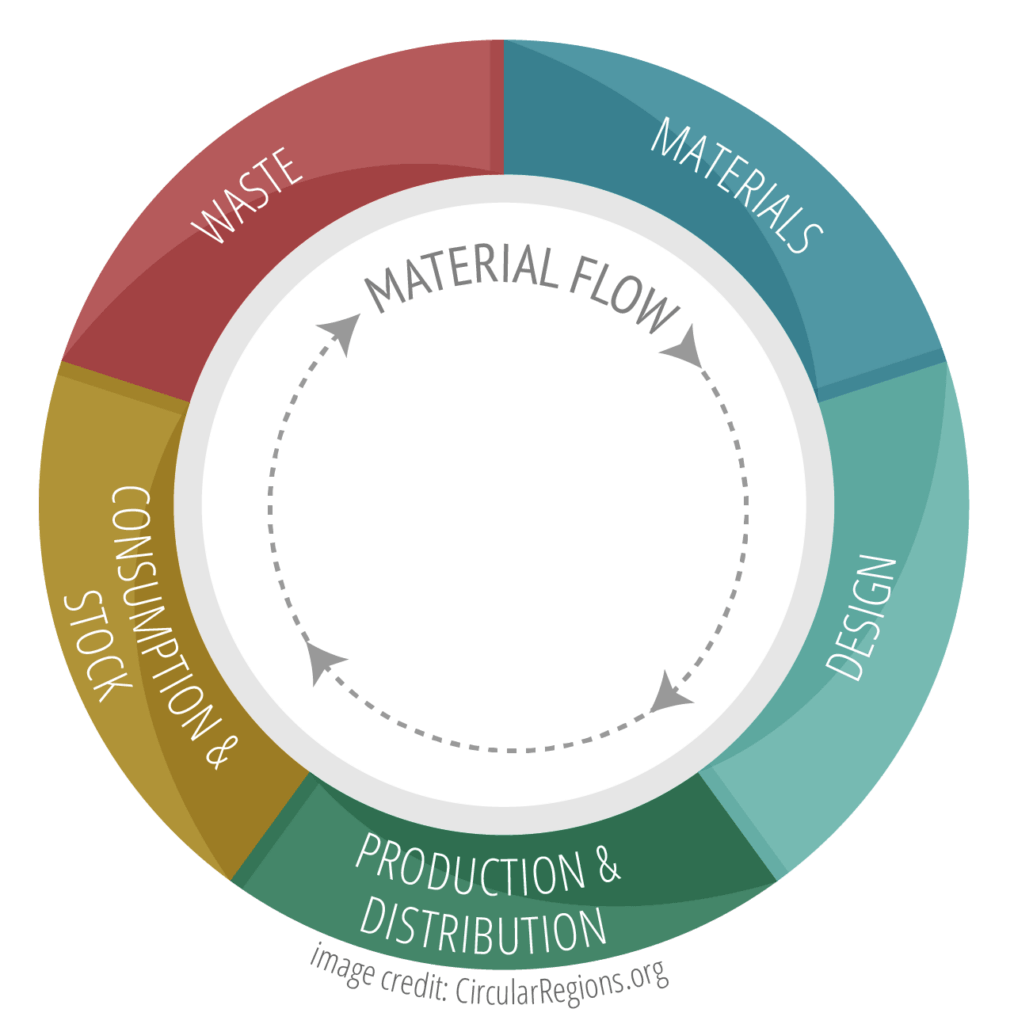

CYCLE PHASE

CASE STUDY MAPPING SOURCE:

- CAN-CECL1

Circular Case Studies by Circular Regions licensed under CC BY-NC-ND 4.0

STATUS & TIMELINE

| Milestone title | Date | Content |

|---|---|---|

| 2007 |

DESCRIPTION

TITLE: Reduce plastic waste

CONCEPT: Creating post consumer plastic pellets as feedstock for new material.

Reduce plastic waste by producing a high-quality, low-carbon replacement for virgin plastic.

Plastic resources being lost to landfill or the natural environment.

Produce high-quality post-consumer recycled plastic pellets that can replace the use of virgin plastic.

We want post-consumer recycled plastic to be a fundamental component of a circular economy in Canada.

LOCAL LANGUAGE DESCRIPTION: English

Login to download a .pdf